PowerMill Ultimate: Building Your Bespoke Arsenal – A Guide to Custom Tool Libraries

PowerMill Ultimate empowers you to not only leverage a vast library of pre-defined cutting tools but also to create and manage your own custom tool libraries. This functionality allows you to tailor your toolset to specific machining requirements, optimize workflows, and ultimately achieve superior machining efficiency. This comprehensive guide delves into the world of custom tool libraries in PowerMill Ultimate, equipping you with the knowledge to build and manage your own bespoke arsenal of cutting tools.

The Power of Customization: Why Create Custom Tool Libraries?

While PowerMill’s standard tool library offers a comprehensive selection of cutting tools, there are several compelling reasons to create custom tool libraries:

Accommodating Non-Standard Tools: Your machining needs might involve specialized cutting tools not readily available in the standard library. Custom tool libraries allow you to define the geometry, dimensions, and cutting parameters of these non-standard tools for seamless integration into your toolpath generation process.

Streamlining Workflows: Frequently used machining operations can benefit from pre-defined tools with specific parameters readily available in a custom library. This eliminates the need for repetitive tool definition and parameter setup, saving time and minimizing errors.

Enhancing Organization: As your machining projects diversify, your tool requirements will grow. Custom tool libraries allow you to categorize tools based on specific criteria (material type, application, shank size, etc.), promoting organization and simplifying tool selection for future projects.

Maintaining Consistency: Custom tool libraries help ensure consistency in your machining processes. By defining and storing preferred tool parameters (cutting speeds, feed rates, etc.) for specific materials or applications, you can guarantee repeatable results across different machining projects.

By embracing custom tool libraries, you unlock a powerful level of control and flexibility within your PowerMill environment, fostering efficiency and optimized machining processes.

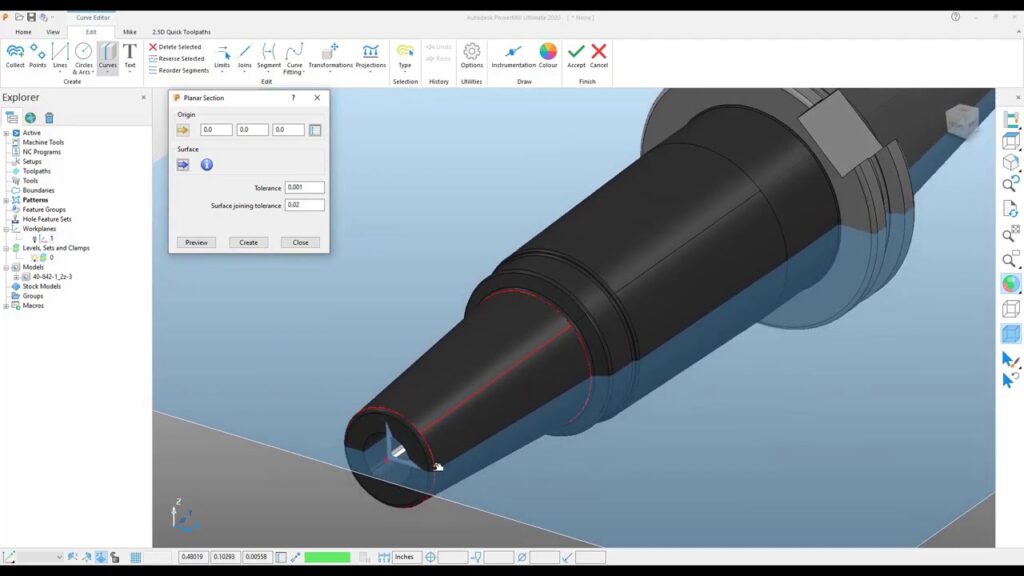

Building Your Bespoke Arsenal: A Step-by-Step Guide

Creating a custom tool library in PowerMill Ultimate involves a few straightforward steps:

Accessing the Tool Library: Launch PowerMill Ultimate and navigate to the “Tools” tab. Within the “Tools” tab, locate the “Tool Library” section. This section provides functionalities for managing both standard and custom tool libraries.

Creating a New Library: Click the “New” button within the “Tool Library” section. A pop-up window will appear, prompting you to name your new custom library. Choose a descriptive name that reflects the intended purpose or contents of the library (e.g., “Custom Carbide End Mills,” “Jigs and Fixtures”).

Defining Your Tools: With your custom library created, you can now populate it with tools. PowerMill offers two primary approaches for defining custom tools:

Manually Defining Tool Geometry: This method allows for precise control over the tool geometry. You can specify parameters like shank diameter, flute length, cutting edge geometry, and corner radius. PowerMill provides various options for defining tool shapes, including cylinders, cones, and more complex geometries using spline curves.

Importing Tool Data: If you have existing tool data in a standard format (e.g., IGES, DXF), you can import it directly into your custom library. This can save time and effort when dealing with pre-defined tools from manufacturers or suppliers.

Assigning Tool Parameters: Beyond geometry, each tool in your custom library requires additional parameters to function effectively within PowerMill. These parameters include:

- Material: Specify the material the tool is constructed from (e.g., high-speed steel, carbide).

- Cutting Parameters: Define recommended cutting speeds, feed rates, and chip loads for different materials being machined with this tool.

- Tool Life: Specify the estimated lifespan of the tool under typical machining conditions. This information can be used for tool wear monitoring and replacement planning.

Organizing Your Library: PowerMill allows you to categorize tools within your custom library based on user-defined criteria. This can involve grouping tools by shank size, material type, application, or any other relevant classification system. Effective organization facilitates easier tool selection and promotes workflow efficiency.

By following these steps, you can establish custom tool libraries that cater to your specific machining needs.

Optimizing Your Workflow: Utilizing Custom Tool Libraries Effectively

Once you’ve created custom tool libraries, here are some strategies to maximize their benefits:

Template Tools: Develop template tools within your library that serve as a starting point for frequently used tools. These templates can be easily customized with specific dimensions or parameters for each machining operation, saving time and ensuring consistency.

Sharing Libraries: If you work collaboratively within a team environment, consider sharing custom tool libraries across workstations. This promotes standardization and streamlines workflows for team members using PowerMill.