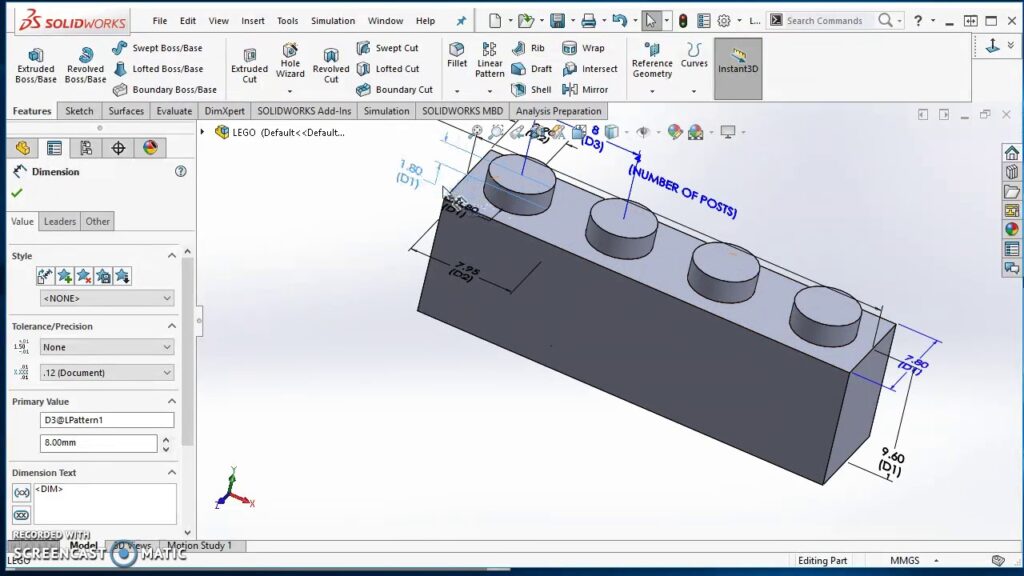

Mastering Configurations in SolidWorks: A Comprehensive Guide

Introduction: SolidWorks, a leading computer-aided design (CAD) software, empowers engineers and designers to create complex models with flexibility and efficiency. Configurations are a powerful feature in SolidWorks that allow users to create variations of a model within the same file. Whether it’s different sizes, colors, or assembly arrangements, configurations enable users to explore design alternatives and manage variations effectively. In this comprehensive guide, we’ll delve into the intricacies of creating configurations in SolidWorks, covering fundamental concepts, essential techniques, and advanced strategies to help you harness the full potential of this versatile tool.

Understanding Configurations in SolidWorks: Configurations in SolidWorks are alternate versions of a model that share the same geometry but differ in properties such as dimensions, features, and display settings. Each configuration can have unique parameters that define its appearance, behavior, and functionality. Before diving into the specifics of creating configurations, it’s essential to grasp some foundational concepts:

- Parametric Modeling:

- SolidWorks employs parametric modeling, where model dimensions and features are driven by mathematical relationships and constraints. Configurations leverage these parametric capabilities to create variations of the model without altering the base geometry.

- Design Intent:

- Configurations enable users to capture design intent by specifying how the model should behave under different conditions. By defining configurations, users can explore design alternatives, perform design iterations, and adapt models to meet specific requirements.

- Configuration Properties:

- Configuration properties include parameters such as dimensions, features, materials, appearances, and suppression states. Users can define multiple configurations within a single model file and switch between configurations to visualize and analyze design variations.

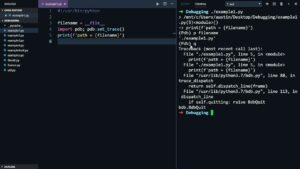

Creating Configurations in SolidWorks: SolidWorks offers intuitive tools for creating and managing configurations, allowing users to customize models and explore design alternatives with ease. Let’s explore the essential steps for creating configurations:

- Define Configuration Variables:

- Begin by identifying the parameters that will vary between configurations, such as dimensions, features, or display settings. These parameters serve as configuration variables and can be controlled using equations, design tables, or manually input values.

- Create New Configuration:

- Once the configuration variables are defined, create a new configuration within the SolidWorks model file. Users can access the Configuration Manager from the FeatureManager design tree and use the Add Configuration command to create a new configuration.

- Customize Configuration Properties:

- Customize the properties of the new configuration by modifying dimension values, adding or suppressing features, changing materials or appearances, and adjusting display settings. SolidWorks provides a PropertyManager interface for editing configuration properties efficiently.

- Repeat for Additional Configurations:

- Repeat the process to create additional configurations as needed, each with its unique set of properties and parameters. Users can create as many configurations as required to cover different design variations, options, or manufacturing scenarios.

Managing Configurations in SolidWorks: SolidWorks provides tools for managing and organizing configurations effectively, ensuring clarity, consistency, and ease of use. Let’s explore the essential techniques for managing configurations:

- Configuration Properties:

- Use the Configuration Properties dialog to specify configuration-specific settings such as name, description, and derived configurations. This dialog also allows users to control features, suppression states, and display configurations for each configuration.

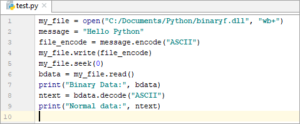

- Design Tables:

- Design tables provide a tabular interface for managing configurations and their associated parameters. Users can create and edit design tables using spreadsheet software or directly within SolidWorks, making it easy to update configuration properties and values.

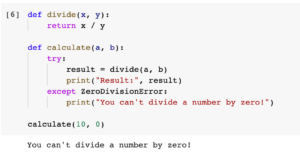

- Equations and Relations:

- Leverage equations and relations to establish relationships between configuration variables and drive design changes dynamically. Equations allow users to define mathematical expressions that link dimensions, features, and other parameters across configurations.

- Display States:

- Utilize display states to control the visibility and appearance of components within configurations. Display states allow users to show or hide components, change colors, apply appearances, and modify graphical properties based on configuration settings.

Advanced Configuration Techniques: In addition to basic configuration tools, SolidWorks offers advanced techniques to enhance configuration workflows and achieve precise design objectives:

- Derived Configurations:

- Create derived configurations to inherit properties from existing configurations and customize specific parameters. Derived configurations streamline the creation of variants by eliminating the need to redefine common properties for each configuration.

- Configuration Publisher:

- The Configuration Publisher tool enables users to publish configurations as independent models or part numbers within the SolidWorks environment. Configuration Publisher facilitates configuration management, documentation, and collaboration across design teams.

- Design Tables with Excel Integration:

- SolidWorks integrates with Microsoft Excel to provide seamless design table functionality within the SolidWorks environment. Users can link design tables to Excel spreadsheets, allowing for bi-directional data exchange and advanced configuration management capabilities.

Best Practices for Configuration Management: To maximize efficiency and maintain design integrity when working with configurations in SolidWorks, it’s essential to adhere to best practices:

- Standardize Naming Conventions:

- Establish standardized naming conventions for configurations, features, and properties to ensure consistency and clarity across design files. Use descriptive names and prefixes to differentiate between configurations and convey their purpose.

- Document Design Intent:

- Document the design intent behind each configuration to provide context and guidance for users. Include descriptions, annotations, and notes to explain the rationale behind design decisions and highlight key considerations for each configuration.

- Validate Configurations:

- Regularly validate configurations to ensure that they meet design requirements and performance expectations. Use tools like design analysis, simulation, and prototyping to verify configuration properties and assess their impact on product performance.

- Version Control and Revision Management:

- Implement version control and revision management practices to track changes and revisions to configurations over time. Use SolidWorks PDM or other version control systems to manage configuration files, track changes, and collaborate effectively across design teams.

Conclusion: Configurations are a powerful feature in SolidWorks that enable users to create, manage, and customize variations of models with ease and efficiency. By mastering the tools and techniques for working with configurations, you can enhance your design capabilities, streamline your workflow, and produce high-quality models that meet design requirements and manufacturing standards. Whether you’re a novice or an experienced SolidWorks user, understanding the principles of configuration management and applying best practices will elevate your design proficiency and enable you to explore design alternatives, adapt models to specific requirements, and optimize product performance effectively.