Navigating Manufacturer Part Assignment in Autodesk Electrical: A Comprehensive Guide

Assigning manufacturer parts to components in Autodesk Electrical is a crucial step in the electrical design process, ensuring accurate representation and compatibility with real-world components. By linking components to specific manufacturer parts, designers can streamline procurement, assembly, and maintenance activities, enhancing efficiency and reducing errors. In this comprehensive guide, we will delve into the intricacies of assigning manufacturer parts to components in Autodesk Electrical, providing detailed instructions, best practices, and expert tips to help you master this essential aspect of electrical design.

Understanding the Importance of Manufacturer Part Assignment

Assigning manufacturer parts to components serves several key purposes in electrical design:

- Accuracy: Linking components to specific manufacturer parts ensures accurate representation of real-world components within schematic diagrams and bill of materials (BOM).

- Compatibility: By selecting compatible manufacturer parts, designers can ensure that components meet project requirements, specifications, and standards.

- Procurement Efficiency: Manufacturer part assignment streamlines procurement processes by providing procurement teams with precise part information, reducing sourcing errors and lead times.

Assigning Manufacturer Parts in Autodesk Electrical

Now, let’s explore the step-by-step process of assigning manufacturer parts to components within Autodesk Electrical:

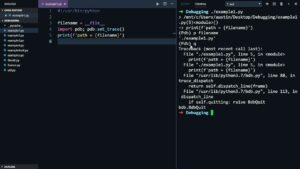

Step 1: Access Manufacturer Parts Database

- Manufacturer Parts Database: Navigate to the manufacturer parts database or library within Autodesk Electrical, which contains an extensive catalog of electronic components from various manufacturers.

- Search and Selection: Use search filters and parameters to locate the specific manufacturer part that corresponds to the component you wish to assign.

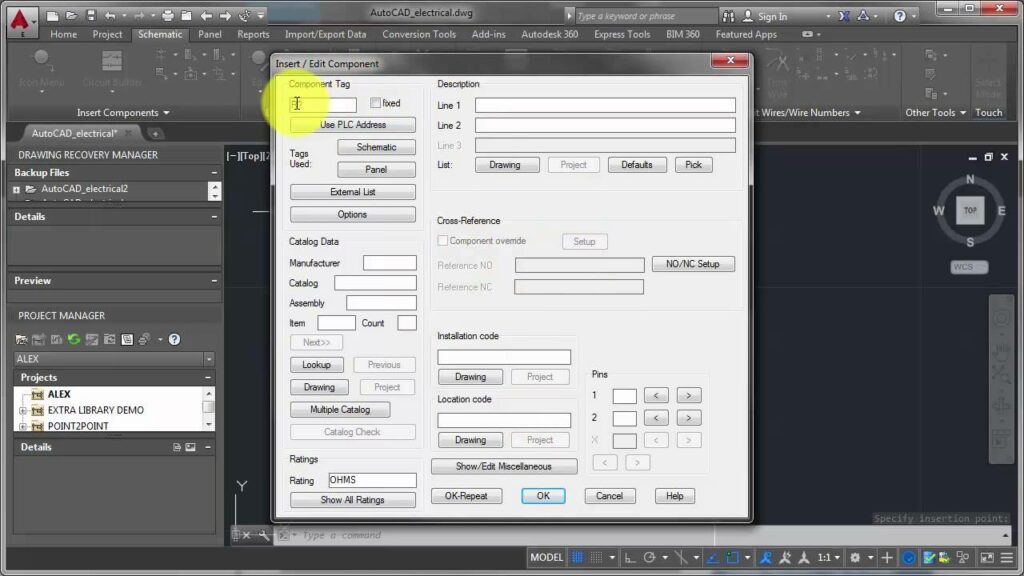

Step 2: Link Components to Manufacturer Parts

- Component Properties: Access the properties of the component within Autodesk Electrical to view and edit its attributes.

- Manufacturer Part Assignment: Select the manufacturer part from the database and assign it to the component by linking it to the component properties.

Step 3: Verify Compatibility and Specifications

- Component Attributes: Review the specifications and attributes of the selected manufacturer part to ensure compatibility with project requirements and design constraints.

- Cross-Referencing: Cross-reference manufacturer part specifications with component datasheets and design documentation to validate suitability and performance.

Step 4: Save and Document Assignment

- Save Changes: Save the manufacturer part assignment within Autodesk Electrical to apply the changes to the component properties.

- Documentation: Document the manufacturer part assignment details, including part number, description, specifications, and vendor information, for future reference and procurement purposes.

Best Practices for Manufacturer Part Assignment

To optimize the process of assigning manufacturer parts to components in Autodesk Electrical, consider the following best practices:

Research and Verification

- Component Verification: Verify the compatibility and suitability of manufacturer parts by referencing component datasheets, specifications, and application notes.

- Cross-Referencing: Cross-reference manufacturer part specifications with industry standards and regulatory requirements to ensure compliance and reliability.

Standardization and Consistency

- Standardized Libraries: Establish standardized libraries of manufacturer parts comprising approved components from trusted vendors to ensure consistency and compatibility across design projects.

- Naming Conventions: Adopt consistent naming conventions and part numbering schemes for manufacturer parts to facilitate organization, searchability, and documentation.

Collaboration and Communication

- Vendor Collaboration: Collaborate with component vendors and suppliers to gather information, obtain datasheets, and validate manufacturer part selections.

- Internal Collaboration: Foster collaboration among design team members, engineers, and procurement specialists to share insights, review part selections, and address any discrepancies or concerns.

Conclusion

Assigning manufacturer parts to components in Autodesk Electrical is a critical aspect of electrical design, ensuring accuracy, compatibility, and efficiency throughout the design and procurement process. By following the steps outlined in this guide and adhering to best practices, you can master the manufacturer part assignment process, streamline procurement workflows, and enhance collaboration and communication among project stakeholders. Whether you’re designing circuits for consumer electronics, industrial automation, or telecommunications applications, proficiency in manufacturer part assignment will empower you to deliver superior results and exceed client expectations.