Mastering Bill of Materials (BOM) Generation and Updates in Autodesk Electrical: A Comprehensive Guide

The Bill of Materials (BOM) serves as a vital document in electrical design, providing a comprehensive list of components and materials required for a project. In Autodesk Electrical, generating and updating a BOM is an essential part of the design process, ensuring accuracy, consistency, and efficiency in procurement, assembly, and maintenance activities. In this extensive guide, we will delve into the intricacies of generating and updating a BOM in Autodesk Electrical, providing detailed instructions, best practices, and expert tips to help you master this critical aspect of electrical design.

Understanding the Importance of Bill of Materials (BOM)

The Bill of Materials (BOM) plays a pivotal role in the electrical design and manufacturing process, serving several key purposes:

- Procurement and Purchasing: The BOM provides a detailed list of components and materials required for a project, facilitating procurement activities and ensuring that the necessary parts are sourced correctly.

- Assembly and Construction: By specifying the components and their quantities, the BOM guides assembly and construction processes, ensuring that the correct parts are used and installed in the appropriate locations.

- Inventory Management: The BOM helps manage inventory levels by identifying the quantity of each component needed, enabling efficient stock replenishment and inventory tracking.

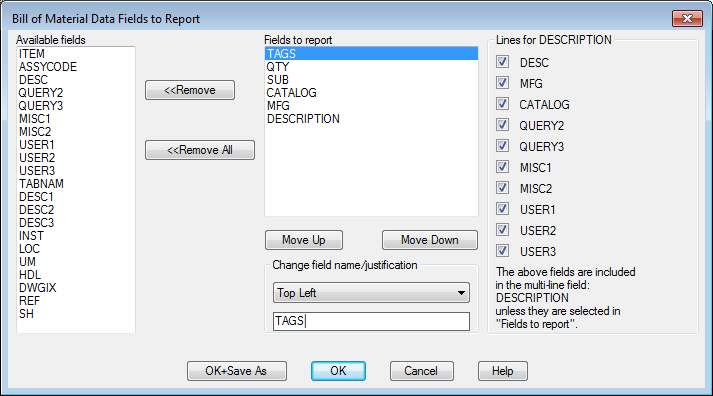

Generating a Bill of Materials (BOM) in Autodesk Electrical

Now, let’s explore the step-by-step process of generating a Bill of Materials (BOM) within Autodesk Electrical:

Step 1: Define BOM Settings

- Project Settings: Access the project settings within Autodesk Electrical to configure BOM generation options such as component inclusion criteria, formatting preferences, and sorting parameters.

- BOM Templates: Choose a suitable BOM template or format that aligns with project requirements and industry standards.

Step 2: Generate BOM Report

- Generate BOM Command: Use the “Generate BOM” command within Autodesk Electrical to initiate the BOM generation process.

- Selection Criteria: Specify the criteria for BOM generation, such as selecting all components within the project, specific circuit assemblies, or components within a designated area.

Step 3: Review and Verify BOM

- BOM Preview: Review the generated BOM report within Autodesk Electrical to ensure accuracy and completeness.

- Verification Checks: Perform verification checks to confirm that all required components are included, quantities are accurate, and formatting is consistent.

Step 4: Export BOM Report

- Export Options: Choose the desired file format for the BOM report, such as Excel spreadsheet, CSV file, or PDF document.

- Save and Export: Save the BOM report to the designated location on your computer or network, ensuring accessibility for stakeholders and collaborators.

Updating a Bill of Materials (BOM) in Autodesk Electrical

After generating a BOM, it’s essential to keep it updated throughout the design process to reflect any changes or revisions. Here’s how to update a BOM in Autodesk Electrical:

Step 1: Modify Component Information

- Component Properties: Update component properties such as part numbers, descriptions, quantities, or specifications as needed within the schematic drawings.

- Revision Control: Implement a revision control system to track changes to component information and ensure consistency between the BOM and schematic drawings.

Step 2: Regenerate BOM Report

- Re-Generate BOM: Use the “Generate BOM” command within Autodesk Electrical to regenerate the BOM report with the updated component information.

- Selection Criteria: Specify the same criteria used during the initial BOM generation process to ensure consistency and accuracy.

Step 3: Review and Verify Updated BOM

- BOM Preview: Review the updated BOM report to verify that component changes and revisions have been accurately reflected.

- Comparison Checks: Perform comparison checks between the previous and updated BOM reports to identify any discrepancies or inconsistencies.

Step 4: Export Updated BOM Report

- Export Options: Choose the appropriate file format for the updated BOM report and save it to the designated location for distribution and use by project stakeholders.

- Documentation: Document any changes or revisions made to the BOM report for future reference and auditing purposes.

Best Practices for BOM Generation and Updates

To optimize the process of generating and updating a Bill of Materials (BOM) in Autodesk Electrical, consider the following best practices:

Consistency and Standardization

- Standardized Formats: Establish standardized BOM formats, templates, and layouts to ensure consistency and uniformity across projects.

- Naming Conventions: Adopt consistent naming conventions for components and materials to facilitate identification and searchability within the BOM.

Collaboration and Communication

- Team Collaboration: Foster collaboration among design team members, engineers, and procurement specialists to ensure that the BOM accurately reflects project requirements.

- Communication Channels: Establish clear communication channels for sharing BOM updates, revisions, and feedback among project stakeholders.

Version Control and Revision Management

- Version Control System: Implement a version control system to manage BOM revisions and track changes made throughout the design process.

- Revision History: Maintain a comprehensive revision history for the BOM, documenting the date, author, and nature of each revision.

Conclusion

Generating and updating a Bill of Materials (BOM) in Autodesk Electrical is a critical aspect of electrical design, ensuring accuracy, consistency, and efficiency in procurement, assembly, and maintenance activities. By following the steps outlined in this guide and adhering to best practices, you can master the BOM generation and update process, streamline documentation workflows, and enhance collaboration among project stakeholders. Whether you’re designing control systems, automation circuits, or power distribution networks, proficiency in BOM generation and updates will empower you to deliver superior results and exceed client expectations.