Exploring Versatility and Efficiency: A Comprehensive Guide to Part and Assembly Configurations in SolidWorks

Part and assembly configurations represent a powerful feature within SolidWorks, enabling designers and engineers to create variations of components and assemblies quickly and efficiently. In this exhaustive guide, we delve into the intricacies of part and assembly configurations in SolidWorks, unraveling their functionality, benefits, and practical applications across various design and engineering disciplines.

Understanding Part and Assembly Configurations:

Part and assembly configurations in SolidWorks allow users to define and manage multiple variations or states of a component or assembly within a single file. These configurations can differ in geometry, dimensions, features, materials, and other properties, providing designers with a versatile framework for exploring design alternatives, accommodating design changes, and optimizing designs for different requirements or scenarios.

At the heart of part and assembly configurations lies the concept of configuration-specific properties, which allow users to customize and control the behavior of configurations independently. These properties include dimensions, features, suppression states, display states, and custom properties, each tailored to the specific needs of the configuration.

Key Concepts of Part and Assembly Configurations in SolidWorks:

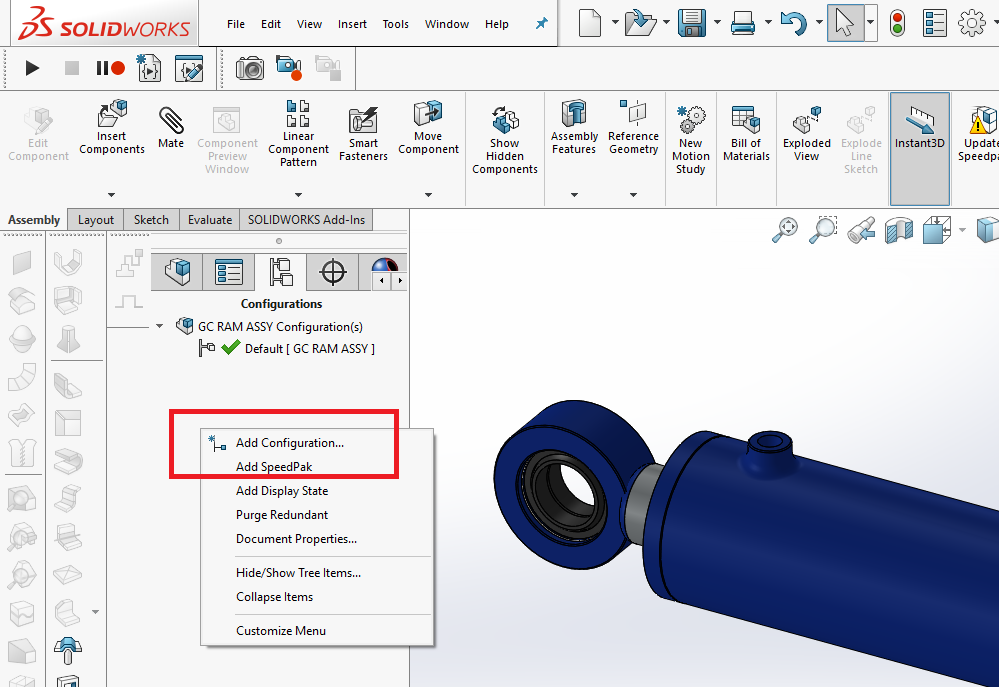

- Configuration Management: Part and assembly configurations are managed through the Configuration Manager, a tabular interface that displays all configurations within the file. Users can create, modify, and switch between configurations seamlessly, organizing them hierarchically and associating them with specific design scenarios or options.

- Derived Configurations: SolidWorks allows users to create derived configurations, which inherit properties from a parent configuration but can be customized independently. Derived configurations streamline the creation of variations by providing a starting point from which users can make incremental changes or modifications.

- Configuration-specific Features: Part and assembly configurations support configuration-specific features, which allow users to tailor features such as cuts, fillets, chamfers, and patterns to specific configurations. This enables users to optimize designs for different requirements or constraints while maintaining a single file for all configurations.

- Design Tables: SolidWorks provides design tables as a powerful tool for managing configurations, allowing users to define and edit configuration parameters in a tabular format. Design tables facilitate mass customization, parametric design exploration, and design automation by providing a structured and intuitive interface for configuring models.

Benefits of Part and Assembly Configurations in SolidWorks:

- Design Exploration: Part and assembly configurations enable designers to explore multiple design alternatives and variations within a single file, facilitating iterative design processes and fostering creativity and innovation. By creating configurations for different design options or scenarios, designers can evaluate trade-offs, compare solutions, and identify optimal designs efficiently.

- Parametric Design: Part and assembly configurations support parametric design principles by allowing users to define dimensions, features, and properties as variables that can be controlled and manipulated parametrically. This enables designers to create flexible, adaptive designs that respond dynamically to changes in requirements or specifications.

- Efficiency and Reusability: Part and assembly configurations promote efficiency and reusability by providing a systematic framework for managing design variations and options. By consolidating multiple configurations within a single file, designers can streamline file management, reduce duplication, and leverage existing designs as templates for new projects or iterations.

- Customization and Personalization: Part and assembly configurations enable mass customization and personalization by allowing users to tailor designs to specific customer requirements or preferences. By creating configurations for different product options, variants, or configurations, designers can accommodate diverse customer needs while maintaining a standardized design platform.

Practical Applications of Part and Assembly Configurations in SolidWorks:

- Product Customization: Part and assembly configurations are widely used in product design and manufacturing for mass customization and product personalization. Designers leverage configurations to create variants, options, and accessories tailored to individual customer preferences, enabling product differentiation and market segmentation.

- Design Variants: Part and assembly configurations support the creation of design variants for different markets, regions, or applications. Designers can create configurations optimized for specific environmental conditions, regulatory requirements, or user preferences, ensuring that products meet diverse customer needs and regulatory standards.

- Design Options: Part and assembly configurations enable the creation of design options and alternatives for internal review, customer presentation, or design validation. Designers can explore different design concepts, configurations, or iterations within a single file, facilitating decision-making and consensus-building processes.

- Parametric Design Exploration: Part and assembly configurations facilitate parametric design exploration by allowing users to define and manipulate design parameters systematically. Designers can create configurations for different design scenarios, constraints, or objectives, enabling iterative exploration of design space and optimization of design performance and efficiency.

Conclusion:

Part and assembly configurations in SolidWorks represent a versatile and powerful feature that empowers designers and engineers to create, explore, and optimize complex designs efficiently. By providing a systematic framework for managing design variations, options, and alternatives, configurations enable designers to streamline design processes, foster creativity and innovation, and meet diverse customer needs and requirements. Whether used for product customization, design exploration, or parametric design optimization, part and assembly configurations remain a cornerstone of modern engineering workflows, enabling users to master complexity and achieve excellence in their designs.